High purity evaporation materials play a huge role in deposition processes to ensure high quality deposited film. Stanford Advanced Materials provides various evaporation materials for both thermal and e-beam evaporation, including metal and ceramic boats, filaments, crucibles and heaters, and e-beam crucible liners.

Month: July 2019

Image Gallery of SAM Sputter Targets

Stanford Advanced Materials (SAM) Corporation is a global supplier of various sputter targets such as metals, alloys, oxides, ceramic materials. We provide sputtering targets for a wide range of applications from ferromagnetic, complex oxides, and semiconducting films.

An Overview of Copper Sputtering Target

Copper sputtering targets, as part of vacuum coating materials, are widely applied in tool coating, optics coating, solar coating, and etc. Copper targets can be put together with metallic copper because they are essentially the same–composed by Cu atoms.

Development of Copper

Copper is one of the earliest metals discovered by mankind and the first metal that humans began to use. Copper beads made of natural copper excavated by archaeologists in northern Iraq are supposed to have been more than 10,000 years old. Methods for refining copper from its ores were discovered around 5000BC and a 1000 or so years later it was being used in pottery in North Africa.

In modern industry, copper was widely used in the power and electronics industries. By the 1960s, copper used in these two industries accounted for 28%. By 1997, these two industries were still the main areas of copper consumption, accounting for Than 25%. Later, copper was widely used in electrical, light industry, machinery manufacturing, construction industry, transportation, and other fields. As far as America is concerned, copper is second only to aluminum in the consumption of non-ferrous materials. Copper has excellent performance and is easy to recycle and recycle. At present, there are already relatively complete recycled copper recycling systems in developed countries. For example, the output of recycled copper in the United States accounts for 60% of the total output, and Germany accounts for 80%.

Copper Sputtering Target Property

Copper is a chemical metal element with the symbol Cu. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orange color. Copper is used as a conductor of heat and electricity, as a building material, and as a constituent of various metal alloys, such as sterling silver used in jewelry, cupronickel used to make marine hardware and coins, and constantan used in strain gauges and thermocouples for temperature measurement.

| Material Type | Copper |

| Symbol | Cu |

| Color/Appearance | Copper, Metallic |

| Melting Point | 1,083 ℃ |

| Density | 8.96 g/cm3 |

| Sputter | DC |

| Type of Bond | Indium, Elastomer |

| Comments | Adhesion poor. Use interlayer (Cr). Evaporates using any source material. |

From Metal Copper to Copper Sputter Target

The copper sputtering target is a kind of copper product made of the metal copper, and it is used in the sputter coating to produce copper thin film. Simply speaking, there are two methods to make copper sputtering target from metal copper.

Casting: melt the raw material of a certain distribution ratio, pour the alloy solution into a mold to form an ingot, and finally machine it to become a sputtering target. The method is smelted and cast in a vacuum.

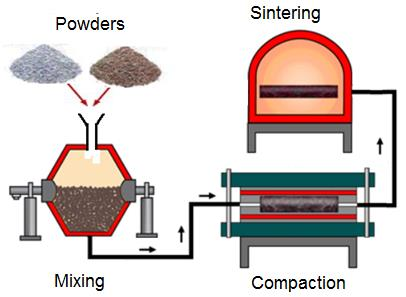

Powder metallurgy: melt the raw material of a certain distribution ratio, cast it into an ingot and then pulverize it, isostatically press the powder, and then sintering it at a high temperature to finally form a target.

Basic Requirement of Copper SputterTarget

In general, when measuring whether the sputtering target meets the primary requirements, one would consider the following indicators:

Purity: Purity has a great influence on the performance of the film produced by sputter coating. Taking copper target as an example, the higher the purity is, the better the corrosion resistance and electrical and optical properties of the sputtered film are.

Impurity content: The impurities in the solid of the target material and the oxygen and water vapor in the stoma are the main pollution sources of the deposition film. Targets for different applications have different requirements of their impurity contents.

Density: The density of the target not only affects the sputtering rate but also affects the electrical and optical properties of the film. Thus, in order to reduce pores in the solids of the target and improve the properties of the sputtered film, the target is usually required to have a higher density.

Grain size and grain size distribution: For the same target, the sputtering rate of the fine-grained target is faster than that of the coarse-grained target; and the thickness of the target sputter-deposited film with a smaller difference in grain size (distributed uniformly) is more uniform.

Information provided by SAM Sputter Targets.

History and Development of Copper

Sorry for that we have not updated the “Metal History” column for a long time. For previous posts of this column, please search the keyword “history”. Today, let us unveil the history of copper.

Copper is one of the earliest metals discovered by mankind and the first metal that humans began to use. Copper beads made of natural copper excavated by archaeologists in northern Iraq are supposed to have been more than 10,000 years old. Methods for refining copper from its ores were discovered around 5000BC and a 1000 or so years later it was being used in pottery in North Africa.

Part of the reason for it being used so early is simply that it is relatively easy to shape. However, it is somewhat too soft for many tools and around 5000 years ago it was discovered that when copper is mixed with other metals the resulting alloys are harder than the copper itself. As examples, brass is a mixture of copper and zinc while bronze is a mixture of copper and tin. For many centuries, bronze reigned supreme, being used for plows, tools of all kinds, weapons, armor, and decorative objects.

Mesopotamia, circa 4500 BC

Pure Metal is ineffective as a weapon and tool because of its softness. But early metallurgy experimentation by the Mesopotamians resulted in a solution to this problem: bronze, an alloy of copper and tin, was not only harder but also could be treated by forging (shaping and hardening through hammering) and casting (poured and molded as a liquid).

The ability to extract copper from ore bodies has been well developed. In today’s Armenia, bronze and copper alloy tools, including chisels, razors, harpoons, arrows and spearheads, have been traced back to the third millennium BC. A chemical analysis of bronze from the region indicates that common alloys of the time contained approximately 87 percent copper, 10 to 11 percent tin, and small amounts of iron, nickel, lead, arsenic, and antimony.

Egypt, circa 3500 BC

The use of copper in Egypt developed almost at the same time as Mesopotamia. The copper pipe used to transport water was used in the King Sa’Hu-Re temple in Abusir, 2750 BC. These tubes are made of thin copper plate with a diameter of 2.95 inches (75 mm) and a pipe length of nearly 328 feet (100 m). The Egyptians also used copper and bronze as mirrors, razors, utensils, weights and balances, as well as obelisks and ornaments on temples. According to biblical references, the Egyptians used a large number of bronze pillars on the porch of the Solomon Palace in Jerusalem (circa 9th century BC), which were 6 feet (1.83 meters) in diameter and 25 feet (7.62 meters) high.

China, circa 2800 BC

By the year 2000 BC, bronzes were produced in large quantities in China. Bronze castings found in Henan and Shaanxi provinces and surrounding areas are considered to be the beginnings of Chinese bronzes, although some copper and bronze artifacts used by the Majiayao have been dated as early as 3000 BC.

Relevant literature shows the direction of metallurgy in China, and discusses in detail the exact proportions of copper and tin used to produce different alloy grades for casting different items such as cymbals and bells, axes, spears, swords, arrows and mirrors.

Modern Development

In modern industry, copper was widely used in the power and electronics industries. By the 1960s, copper used in these two industries accounted for 28%. By 1997, these two industries were still the main areas of copper consumption, accounting for Than 25%. Later, copper was widely used in electrical, light industry, machinery manufacturing, construction industry, transportation and other fields. As far as America is concerned, copper is second only to aluminum in the consumption of non-ferrous materials. Copper has excellent performance and is easy to recycle and recycle. At present, there are already relatively complete recycled copper recycling systems in developed countries. For example, the output of recycled copper in the United States accounts for 60% of the total output, and Germany accounts for 80%.

Information provided by SAM Sputter Targets.

Related Copper Products: Copper Sputtering Target

Guide Book: Sputtering Targets Preparation, Cleaning, Installation and Packing

Preparation before using the target

It is very important to keep the vacuum chamber clean. Residues formed during target sputtering collect moisture and other contaminants, directly affecting the success rate of vacuum coating. If the sputtering chamber is not clean enough, the sputter gun and the sputtering target will often short-circuit or exceed the target arc to discharge, filming surface roughness and chemical impurities. In addition to the vacuum chamber, the dark area shield, cavity walls and adjacent surfaces need to be kept clean. When cleaning the vacuum chamber, we recommend using a glass ball to blast the dirty parts, while using compressed air to remove spilled residue from the periphery of the cavity, and then gently polishing the surface with alumina impregnated sandpaper. After polishing, wash with alcohol, acetone and deionized water. It is recommended to use an industrial vacuum cleaner for auxiliary cleaning.

In addition, in order to ensure coating characteristics, it is also necessary to wash and dry the sputtering gas (argon or oxygen). After the substrate is placed in the sputtering chamber, air needs to be extracted to achieve the vacuum state required for the process.

When using the target, wear clean protective gloves and avoid direct contact with the target.

Target cleaning

The purpose of cleaning the sputtering target is to remove any dust or dirt that may be present on the target surface. Metal sputtering targets can be cleaned in four steps:

In the first step, the target is wiped with a soft, lint-free cloth soaked in acetone;

The second step is to clean the target with alcohol;

The third step is to wash the target with deionized water;

In the fourth step, the target was placed in an oven and dried at 100 degrees Celsius for 30 minutes.

For oxide ceramic sputtering targets, it is recommended to use a “langue-free cloth” for cleaning. After removing the contaminated area, the target is flushed with high pressure, low moisture argon to remove any contaminating particles that may create an arc in the sputtering system.

Target installation

During target installation, it is important to ensure a good thermal connection between the target and the stabilizing wall of the sputter gun. If the degree of warpage of the stave or backing plate is severe, the thermal conductivity of the target will be greatly affected, resulting in heat not being dissipated during the sputtering process, eventually leading to cracking of the target.

Target packaging and transportation

All targets should be packaged in a vacuum-sealed plastic bag with a moisture barrier. The outer packaging is usually a wooden box with an anti-collision layer around it to protect the target and rear targets from damage during transportation and storage.

For more information, please visit https://www.sputtertargets.net/.